Products

Proressional Solid state high frequency welding machine Supplier For More Than 10 Years

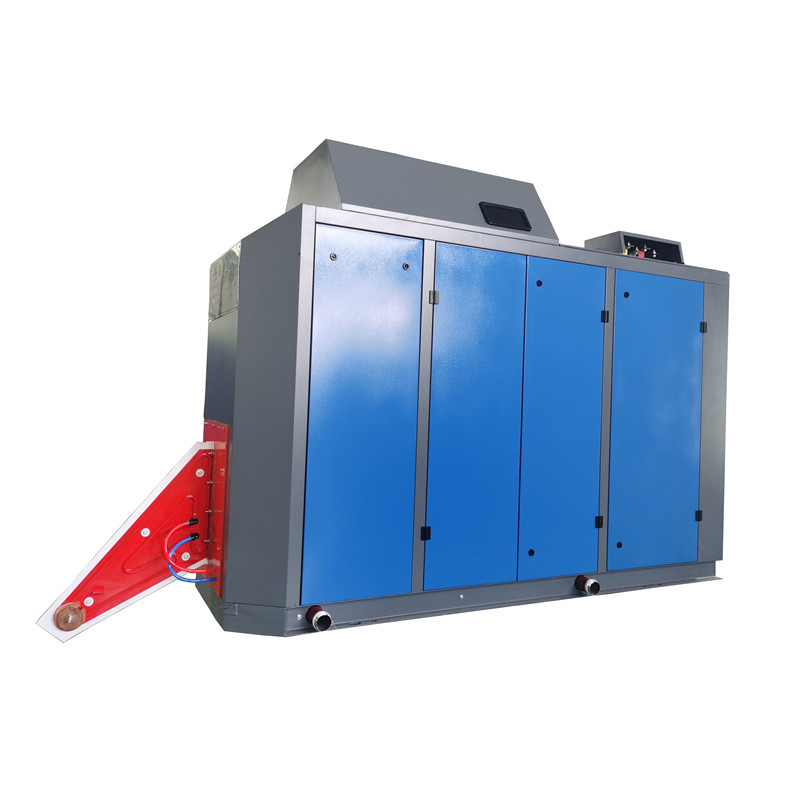

Wholesale Price China Hf Solid State Welder - 100KW Series connection type IGBT Integrated Solid State H.F. Welder pipe making machine supplier – Mingshuo

Wholesale Price China Hf Solid State Welder - 100KW Series connection type IGBT Integrated Solid State H.F. Welder pipe making machine supplier – Mingshuo Detail:

● Diode all wave rectifying add IGBT chopping to replace SCR rectifying,it’s improving the power factor;The DC part and inverter part into one cabinet,which reduce the waterway and circuit between the cabinets,which is effectively avoiding the electrical interference and reducing the installation time.

● The inverter part is consisted of MOSFET single phase invert bridge in parallel style.Each bridge’s design power is 120kW/60kW.We adopt building block mode to pile up power,it’s very convenient to install and maintain because every single bridge board is designed as drawer structure consisted of slide way.

● We adopt matching transformer to realize power combination,also we adopt sub-resonance,no-welding transformer output mode and make resonance directly by tank resonance capacitor (low voltage) and inductor to achieve steel pipe welding power transmission by output lead.

● Use sealed box and install overhead air conditioning.

| Main Design Index of Solid State H.F. Welder | |

| Output power | 100kw |

| Rating Voltage | 450V |

| Rating Current | 250A |

| Design Frequency | 400~450kHz |

| Electricity Efficiency | ≥90% |

| Pipe material | Carbon steel |

| Pipe diameter | 12-32mm |

| Pipe wall thickness | 0.4-1.5mm |

| Welding Mode | Induction type of High Frequency Solid State Welding Machine |

| Cooling Mode | Use Air-Water cooler system or water water cooling system to cool induction type 100kw solid state high frequency welder |

Online support,Field installation,commissioning and training,Filed maintenance and repair service

Building material shop,construction works,Manufacturer plant, Tube mill

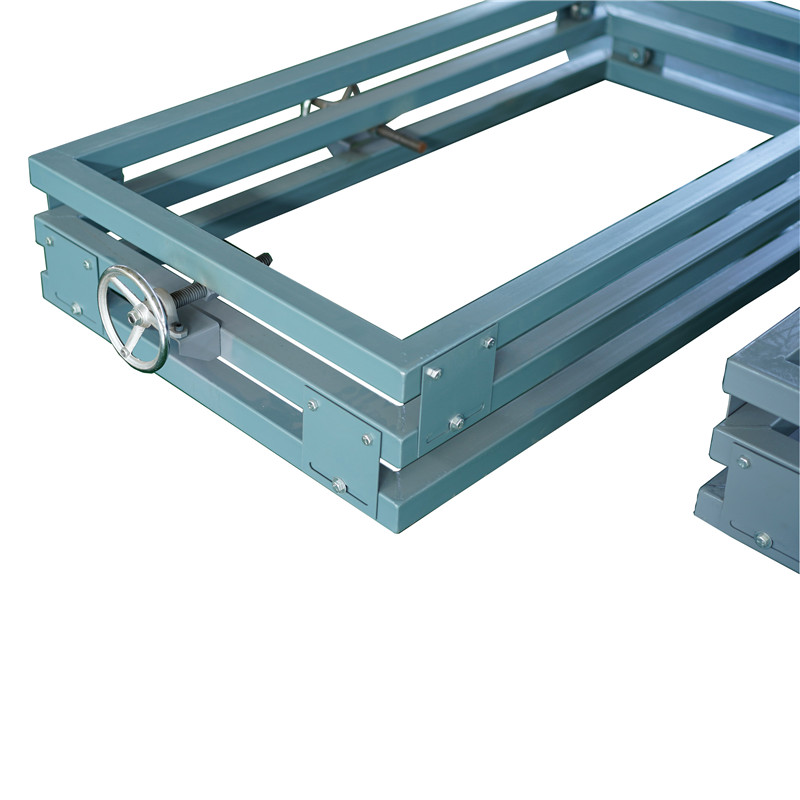

Product detail pictures:

Related Product Guide:

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for Wholesale Price China Hf Solid State Welder - 100KW Series connection type IGBT Integrated Solid State H.F. Welder pipe making machine supplier – Mingshuo , The product will supply to all over the world, such as: Croatia, Switzerland, Nairobi, Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.