Products

Proressional Solid state high frequency welding machine Supplier For More Than 10 Years

500KW Series connection separated SCR Solid state high frequency welder — ERW Pipe making machine which welding steel tube straight seam

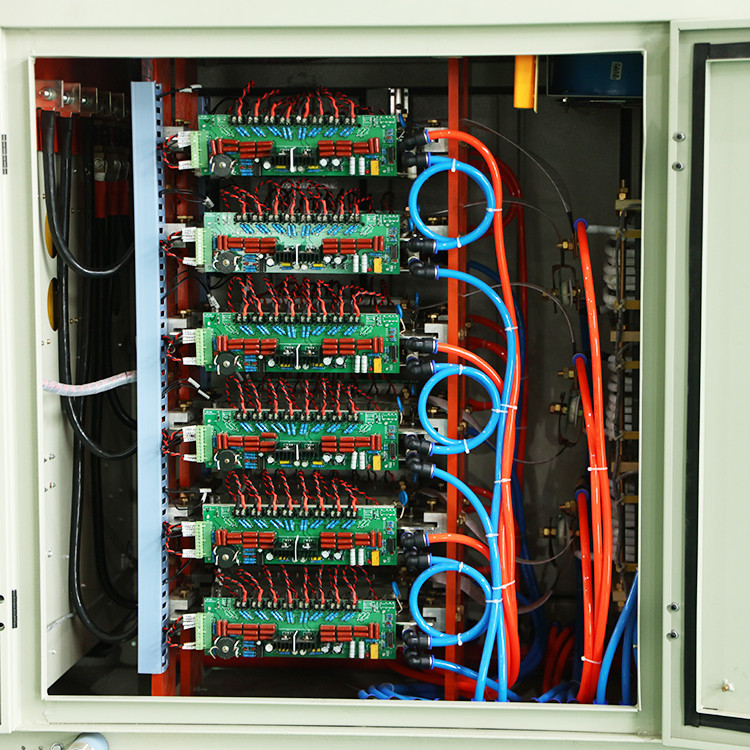

The switch cabinet and rectifier are designed integrally, which not only completes the function of switch cabinet, but also has the rectifier control function of solid-state high-frequency welding machine, which is also called thyristor(SCR) welding machine

Switch Rectifying Cabinet--- main parts of solid state HF Welder

●Install incoming disconnect switch,incoming current meter, voltage meter(switchable) and incoming voltage3 indicating light.

●Install 3-phase full-controllable thyristor rectifying bridge to achieve power regulation of H.F. welders.

●Install flat wave reactor,flat capacitor and filter to increase semi-wave coefficient.

Inverter Output Cabinet--main parts of solid state High Frequency Welder

●The inverter part is consisted of MOSFET single phase invert bridge in parallel style. Each bridge’s design power is 120kW/60kW.We adopt building block mode to pile up power,it’s very convenient to install and maintain because every bridge board is designed as drawer structure consisted of slide way.

●We adopt matching transformer to realize power combination,also we adopt sub-resonance capacitor(low voltage) and inductor to achieve steel pipe welding power transmission by output lead.

●Use sealed box and install overhead air conditioning.

Solid State High Frequency Welder

HMI and fault diagnosis system

●Adopt PLC and touch screen to form perfect HMI system.

●Realize integrated automatic control of welder system.

●Fault display and diagnosis system.

| Main Design Index of Solid State H.F. Welder | |

| Output power | 500kw |

| Rating Voltage | 450V |

| Rating Current | 1250A |

| Design Frequency | 200~300kHz |

| Electricity Efficiency | ≥90% |

| Pipe Material | Carbon steel |

| Pipe Diameter | 76-114 mm |

| Pipe Wall Thickness | 3.0-6.0mm |

| Welding Mode | contact type of High Frequency Solid State Welding Machine |

| Cooling Mode | Use Water-Water cooler system to cool induction type 500kw solid state high frequency welder |

| After Sale Service | Online support,Field installation,commissioning and training,Filed maintenance and repair servic |

The welding of steel tube, stainless steel tube, aluminum tube, copper tube, H-beam and special section tube.